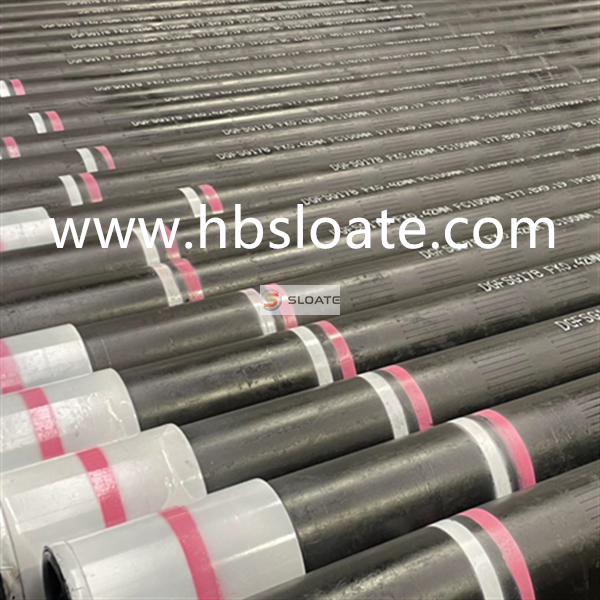

Slottted Liners

slotted Liners

- 1.Range:from 1.9inch to 20 inch

- 2.Standard: API/ISO/GB/T

- 3.Material:J55/K55/N80/L80-1/L80-13Cr/P110/Q125 etc

- 4.Slotted Width:(0.15~20)mm ±0.03mm;

- Product description: J55/K55/N80/L80/P110/BTC/LTC/STC/Premium Threading/Oil casing,Water Well Casing Pipe,Steel Casing pipe,Tubing,Slotted Liners,Precision Punched Screen,Screen Pipe from Hebei Sloate,Qingxian,China,AL

1.Sloate OCTG Products For Tubing Specifications:

Tubing products rating from 1.9inch to 4 1/2 inch, can process Seamless Pipe,ERW Pipe,the,material is J55/K55/N80/L80-1/L80-13Cr/P110/Q125 etc

Standard:

API SPEC 5CT、ISO 11960-2004、GB/T 19830-2011

Type of Threading,Connections:

Non-upset ends (NUE),External upset ends (EUE),Premium gas-tight connectors,Others special connectors

Application:

oil well extracting ,water well,Drilling,Gas,borewell,borehole

Features:

Good physical dimension accuracy and stable physical and chemical property;

Casing possesses remarkable collapsing strength, generally exceeding over 15% of API standard value;

OCTG products surface quality is domestically in the lead.

Whole series of API OCTG(Tubing and Casing )mainly indicate the steel pipes produced as per API SPEC 5CT specification, used for exploiting resources such as petroleum and natural gas etc. Tubing used to extract oil and natural gas, casing used as wall of oil and gas well bore.

2.Chemical Compositions of OCTG,Casing Pipe,Tubing,Slotted Liners

|

Standard |

Grade |

Chemical compositions(%) |

|||||||||

|

API SPEC 5CT |

J55 |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

|

K55 |

0.3~0.39 |

0.2~0.35 |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

/ |

/ |

|

|

N80 |

0.3~0.38 |

0.2~0.35 |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ |

/ |

/ |

0.11~0.16 |

|

|

L80 |

0.1~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~14.0 |

≤0.20 |

≤0.20 |

/ |

/ |

|

|

P110 |

0.2~0.39 |

0.1~0.37 |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~1.10 |

≤0.20 |

≤0.20 |

0.15~0.25 |

≤0.08 |

|

3.Mechanical Properties of OCTG,Casing Pipe,Tubing,Slotted Liners

|

Grade |

Type |

Total Elongation under load (%) |

Yield Strength (min)Mpa |

Yield Strength (max)Mpa |

Tensile Strength min Mpa |

Hardness Max (HRC) |

Hardness Max (HBW) |

|

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

|

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

C90 |

- |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

|

C95 |

- |

0.5 |

655 |

758 |

724 |

- |

- |

|

T95 |

- |

0.5 |

655 |

758 |

724 |

25.4 |

255 |

|

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

|

Q125 |

All |

0.65 |

862 |

1034 |

931 |

- |

- |

Producing Chart:

Why Choose Sloate

Nearly 10 years manufacturing experience in OCTG Products

Material with High Performance Fabricating and Manufacturing

Top Quality Products,API 5CT, ISO9001, ISO14001, certificates

Challenging prices for giving customers the greatest benefits

Fast response time, we promise to reply customer’s email within 24 hours

Attractive lead times, plenty of equipment and workers to ensure the delivery on time

Sloate sell its products to customers in China and abroad.

Such as Middle East,PDO,Russian,Luke Oil,South American,

PDVSA,US,Canada,Anton Oil,Europeans,Germany,BP etc.

Latest News

Contact Us

Contact: Liu

Phone: +86 18103379998

Tel: +86-317-3066898

Add: Qingxian,Hebei Province, China

casingpipe

casingpipe casingpipe

casingpipe